- Contact Person : Mr. Wang Ryan

- Company Name : Xinxiang Xinda Energy Equipment Co., Ltd.

- Tel : 86-373-2068419

- Fax : 86-373-2068418

- Address : Henan,XINXIANG,C2201,WUXING MANSION ,JINSUI ROAD,XINXIANG,CHINA

- Country/Region : China

Related Product Searches:professional High Yield XD-10CAP waste tyre oil to diesel machine,High Quality,waste tyre oil to diesel machine, waste tyre recycling fuel oil machinery,XD-10CP

>> Technical Parameters of waste tyre oil to diesel machine

1) the model and capacityNo. Model Reactor Size Weight Volume Space Required Capacity

No. | Model | Reactor Size | Weight | Volume | Space Requared | Capacity | Note |

1 | XD/10 | 2600mm*6600mm | 38MT | 35m³ | 150-200 s.q.m | 10MT/Batch | 3Batches 2Days |

1) Fuel: the fuel material can be FUEL OIL,HEAVY OIL,COAL,FIREWOOD.

2) Processing time for one batch

No. | Model | Feeding Time | Processing Time | Cooling Time | Discharge Carbon Time | Delivery Time | Installation &Training Time |

1 | XD/10 | 3-4hrs | 10-12hrs | 3-4hrs | 3-4hrs | 30days after getting deposit | 20days |

3) End product percentage (take waste tyre as an sample)

Fuel Oil | Carbon Black | Steel Wire | Waste Gas |

40%-45% | 35%-40% | 10%-15% | 10% |

4) Machine Motor Power

No. | Model | Speed Reducer | Fan | Blower | Oil Pump | Water Pump |

1 | XD/10 | 5.5KW | 7.5KWs | 1KW | 1.5KW | 1.5KW |

5) Containers Required

No. | Model | 40”HQ | 40”FR Open Container |

1 | XD/10 | 1 | 1 |

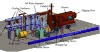

>> Flow Chart of waste tyre oil to diesel machine

waste tyre oil to diesel machine Reactor directly decides the machine‘s safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

Safety

1. waste tyre oil to diesel machine With an auto welding machine for the reactor, it can not only greatly improve working efficiency but also guarantee the quality of welding seam, thus avoid explosion caused by gas leak. Professional heating treatment and x-ray detection chamber are especially for welding.

2. Vacuum system will prevent oil gas from going back to reactor and causing accident.

3. Professional thermometer, pressure gauge and safety valve.

4. It is dangerous to burn exhaust gas (C1 to C4) without any safety measures. In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Long service life of waste tyre oil to diesel machine

1. Material: Q245R/345R special steel plate, thickness 14-16mm

2. Welding: Automatic welding machine with heating treatment and x-ray detection will prolong the service life of reactor to the max.

3. The service life of the reactor will be 5-6 years

professional High Yield XD-10CAP waste tyre oil to diesel machine