- Contact Person : Mr. Wang Ryan

- Company Name : Xinxiang Xinda Energy Equipment Co., Ltd.

- Tel : 86-373-2068419

- Fax : 86-373-2068418

- Address : Henan,XINXIANG,C2201,WUXING MANSION ,JINSUI ROAD,XINXIANG,CHINA

- Country/Region : China

Related Product Searches:professional High Yield XD-08CAP waste engine oil to diesel,High Quality,waste engine oil to diesel, waste tyre to diesel plant,XD-08CP

>> Structure and principle of waste engine oil to diesel

* whole parts

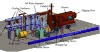

The whole pyrolysis system is composed by 16 parts,which are reactor,Insulation

layer,Desulfurization,deduster,Draft fan,Chimney,Water film cyclone,Condenser,Water tank,Cooling tower(optional),Gas recycle system,Oil tank,Gas separate,Waste gas burner,Furnace,Blower,Carbon black slag system.

The keys of pyrolysis plant are reactor and cooling system.

* Reactor

waste engine oil to diesel Reactor directly decides the machine's safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

>> Features of waste engine oil to diesel

Main characters

1.Heating system

Reactor of used tyres rubber oil plant

Q345R boiler steel and the thickness is 14mm and 16mm,the thickness would be changed according the customers'requirments. The main engine use horizontal-type of 360°structure-0.8 r/min

2.Separation system

Gas separator & Depositing tank

Depart the heavy oil and impurities from the oil gas to purify the oil.

3.Condensing system

Generally speaking , waste engine oil to diesel for all the raw material all be finished by heating to gasification and cracking, and then cooling to get oil, so they key is the relationship between the yield rate and condensation. So the best and easy way is to increase the condense area so as to get higher yield rate.

4.Dedusting system

Desulfurization dedusting, Water film cyclone

Desulfurization dedusting:remove the sulphur(when use coal as fuel) and dust

Water purification: for the second removal.

5.Waste gas recycles system

Water seal & Spray fire gun

In the process of refining oil, when the gas is heated up to 150 , it will produce a large amount of gasCH4& C4H8 ,which cannot convert to liquid at normal temperature and normal pressure. However, these gases can be used as fuel, which is not only environment protection but also energy conservation

6.Carbon black recycles system

Heaving dragon screw conveyer

The solid residual will be left after the catalyst splitting from scrap plastic, approximately take up 5% to 10% of the waste tire.

Its main component is the black carbon, which can be used as raw materials in industry, as well could be mixed with the pulverized coal ash to produce the raw material of the thermal power plant, and also could be applied to the manufacturingof the pulverized coal ash brick

>> Technical Data of waste engine oil to diesel

ITEM | CONTENT | ||

equipment’s model | XD-06 | XD-08 | XD-10 |

Daily Handling capacity | 6 tons | 8 tons | 10 tons |

Door's model | Semi-open door | Semi-open door | Semi-open door |

Structure Form | Horizontal type | Horizontal type | Horizontal type |

Raw material | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic |

Material of reactor | Q345R thickness 14mm | Q345R thickness 14mm | Q345R thickness 14mm |

Main engine rotating speed | 0.4R /min | 0.4R /min | 0.4R /min |

Power | 10-15KW | 10-15KW | 10-15KW |

Cooling Mode | Water | Water | Water |

Consumption of Cooling water | 0.2 | 0.3 | 0.4 |

Heating Mode | Direct | Direct | Direct |

Installation | Main engine integral installation | Main engine integral installation | Main engine integral installation |

Noise dB (A) | <=85 | <=85 | <=85 |

Machine dimension(mm) | D2000*L6000 | D2200*L6600 | D2600*L6600 |

Working Mode | Intermittent | Intermittent | Intermittent |

professional High Yield XD-08CAP waste engine oil to diesel